- Treatment of industrial wastewater.

- Recovery of liquid and water-soluble waste.

- Transport of liquid waste, collection directly from the customer.

- Carrying laboratory tests of sewage, water.

A method for providing waste

- The, so-called, loose – tank.

- Pallet container (IBC, ASP, etc.) returnable and non-returnable.

The main tasks of treatment include the collection and recycling of water contaminated with industrial waste. This allows to relieve the biological sewage treatment plants, which previously took over a large part of the burden of receiving the waste, which disturbed their biology and proper functioning.

Technologies

Industrial Wastewater Treatment Plant was founded as the result of market diversification of industrial waste management by the Sanitatry Work Company Sanator-Bis Sp. z.o.o. produced mainly in Poland. What has been applied is an innovative technology of sewage treatment that allows comparison of the process in a continuous system. Launching the plant allowed the implementation of purchased solutions being the effect of research and development concerning the unusual wastewater treatment, with which Sanator-Bis Sp. z.o.o. encountered in the course of its long history.

The high quality of our services is ensured by staff trained in the field. Our sewage treatment plant also allows to carry out further work on the development of new methods of management of mainly liquid industrial waste.

Innovative technology of wastewater treatment is based on an innovative method of dosing of chemicals, which allows for precise preparation of substance composition depending on the type of waste and it improves efficiency of processes such as, among others, sedimentation, flotation, decantation.

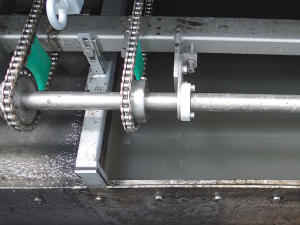

Technological line of our plant is composed of the following modules: a rotary screen of reception station, tanks for the initial phase separation, emulsion separation installation, recovered oil and pretreated water tanks, vibrating drainage containers type EWC for dewatering sludge, control cabinet with control system and software.

Processes of wastewater treatment

Decantation

Liquid phases of liquids of different densities are arranged in layers and are removed, each separately.

Flotation

Part of a stream of initially purified water is collected. This water, aerated with fine bubbles of air and subjected to high pressure, is injected into the stream of raw wastewater. The air bubbles expand in the form of millions of microscopic particles, which are foci of condensation of impurities suspended in the effluent. The bubbles expand elevating contamination to the surface and forming of the scum sludge on the surface.

Precipitation

The setting of the pH value is achieved by the addition of organic sedimenting agents precipitates the impurities dissolved in the water, such as light hydrocarbons, heavy metals, substances increasing COD and AOX values to form of a slurry.

Flocculation

The slurries floating in the water are binding into the a hydrated coating of organic microflocs. The addition of the polymer causes the growth of the flocs by grouping them together until they reach the size of approx. 10 mm.